How an Aluminum Casting Company ensures quality in every project

Wiki Article

Discover the Crucial Advantages of Specialist Shop Providers for Your Manufacturing Needs

Specialist shop services supply substantial advantages for manufacturers looking for premium spreadings. These services combine sophisticated innovation with skilled workmanship to accomplish precise results. By contracting out to experienced foundries, business can boost price effectiveness and reduce production delays. In addition, the ability to tailor and scale production offers compelling possibilities. As sectors advance, understanding these advantages ends up being significantly vital for preserving a competitive edge. What various other elements should manufacturers think about in this partnership?Improved Top Quality and Accuracy in Castings

In today's affordable production landscape, the demand for improved quality and accuracy in spreadings has actually ended up being progressively crucial. Specialist factory services play a crucial role in meeting these needs by utilizing advanced innovations and skilled workmanship. These solutions assure the production of spreadings that not just fulfill yet usually surpass industry criteria for dimensional precision and surface area coating.The integration of computer-aided design (CAD) and simulation strategies allows shops to enhance the spreading process, decreasing flaws such as porosity and misalignment. The use of top notch materials and rigorous quality control gauges more boosts the reliability and toughness of the last item.

Cost Effectiveness and Time Cost Savings

While many makers seek to boost their functional effectiveness, professional shop services supply a critical advantage by noticeably decreasing costs and saving time throughout the production process. By contracting out casting needs to specialized factories, firms can remove the costs related to maintaining in-house facilities and competent labor. This method reduces expenses and permits suppliers to designate sources better.Additionally, specialist factory services enhance the production timeline. With developed workflows and progressed techniques, these solutions help with quicker turnaround times, allowing manufacturers to satisfy tight deadlines and respond without delay to market demands. The decrease in production hold-ups not just decreases supply costs but also boosts capital.

Inevitably, engaging with professional factory services converts to a more effective production process, where financial savings in both time and expenses can extremely boost a business's affordable side in the sector. This effectiveness permits suppliers to focus on core organization tasks while making certain high-quality deliverables.

Access to Advanced Innovation and Expertise

Accessing advanced innovation and experience via expert factory solutions greatly boosts a manufacturer's capacities. By leveraging state-of-the-art tools and ingenious procedures, shops can produce high-quality elements that satisfy stringent sector standards. This access enables manufacturers to benefit from the most recent improvements in materials scientific research, casting strategies, and high quality control measures, guaranteeing that their products are not only competitive however also reputable.Additionally, the know-how of competent engineers and professionals within professional factories gives vital assistance throughout the manufacturing process. Their understanding allows manufacturers to determine potential issues early, maximizing styles and decreasing the risk of flaws. This collaborative strategy promotes enhanced product efficiency and sturdiness.

In an ever-evolving market, the assimilation of sophisticated modern technology and specialized understanding settings producers to adjust swiftly to altering demands, inevitably bring about enhanced productivity and development. By utilizing professional shop services, suppliers can guarantee they continue to be at the center of their market.

Personalization and Adaptability for Diverse Projects

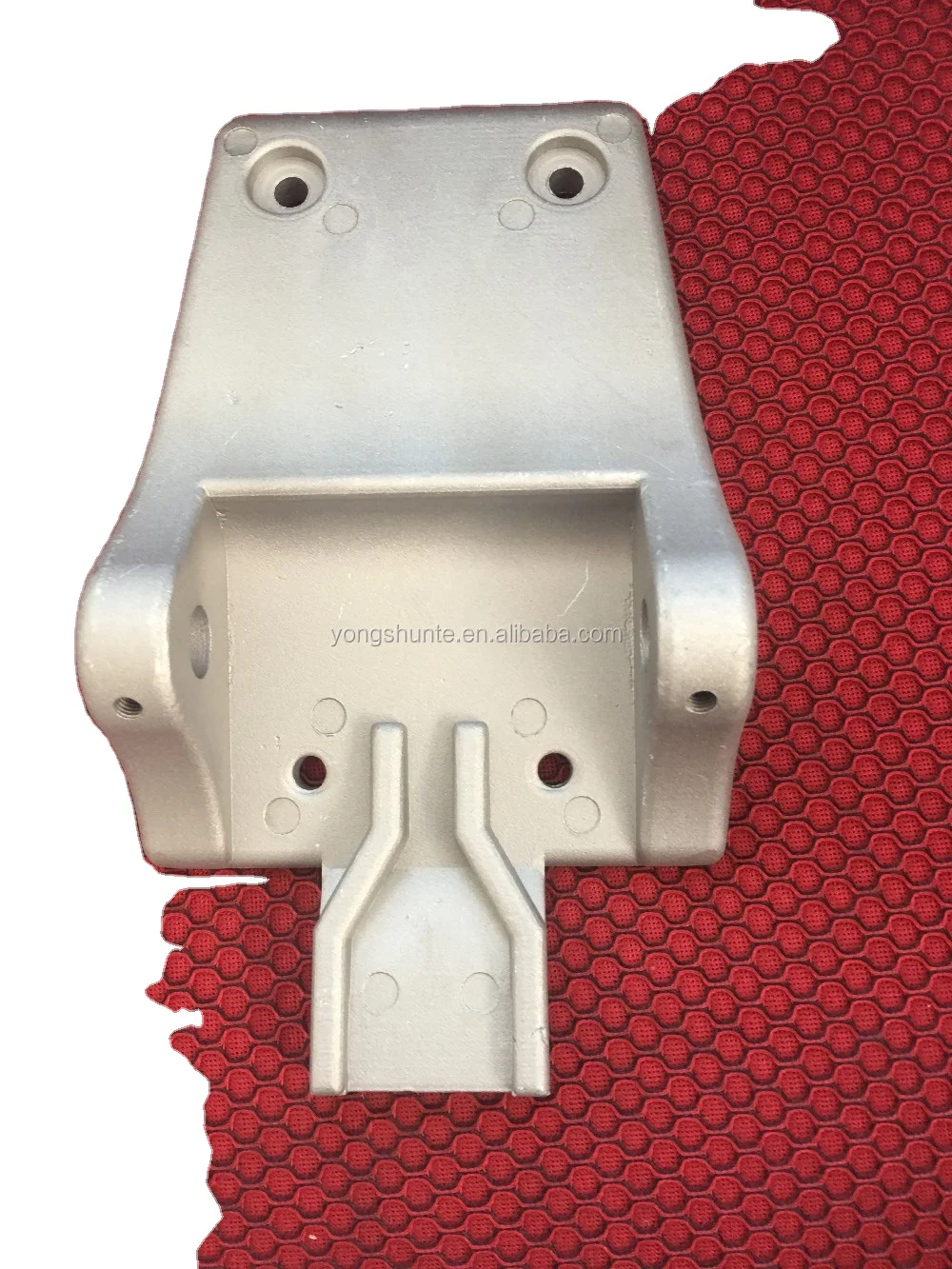

Professional foundry solutions provide significant customization and flexibility, dealing with a wide variety of job demands. aluminum casting. By using innovative methods and technologies, these solutions can produce parts tailored to particular dimensions, products, and visual preferences. This adaptability is important for industries that demand special styles and requirements, such as aerospace, automotive, and medical fieldsClients gain from visit homepage the capability to collaborate carefully with factory professionals, guaranteeing that their distinct requirements are satisfied throughout the manufacturing process. Whether it includes modifying mold and mildew styles or readjusting alloy structures, professional foundries can accommodate numerous demands that improve the last item's capability and performance.

This degree of customization extends to small-batch manufacturings, enabling services to innovate without the restraints of standardization. Inevitably, professional shop solutions encourage manufacturers to understand their visions, supplying them with the flexibility essential for diverse and progressing task needs.

Boosted Production Scalability and Reliability

Exactly how can foundry services assure both scalability and integrity in manufacturing? Specialist factory solutions use innovative technologies and approaches that enhance both elements. By using automated processes and maximized process, shops can adjust manufacturing quantities efficiently, ensuring they fulfill varying market demands.In addition, a dedication to quality assurance and extensive testing methods establishes a trustworthy result that customers can depend upon. This dependability is crucial for keeping long-term collaborations and conference strict deadlines. The assimilation of information analytics likewise allows factories to expect production obstacles and minimize dangers proactively.

Ultimately, the mix of flexible production techniques and stringent top quality procedures settings shop solutions as a cornerstone for services looking for scalable and constant production solutions. Organizations leveraging these services can confidently expand their procedures, knowing they have a reputable companion to sustain their development.

Frequently Asked Inquiries

What Materials Can Be Utilized in Expert Factory Solutions?

Specialist foundry solutions utilize different products, consisting of light weight aluminum, steel, bronze, and iron. These products are chosen for their one-of-a-kind homes, viability for particular applications, and ability to fulfill the varied requirements of various production processes.How Do I Pick the Right Foundry Company?

Picking the appropriate foundry company includes reviewing their experience, top quality of materials, production abilities, and client evaluations (Aluminum Casting Company). In addition, evaluating their technical improvements and interaction abilities can assist assure a successful partnership for making jobs

What Is the Common Lead Time for Casting Projects?

Regular lead times for casting projects vary, usually varying from a few weeks to several months. Factors influencing this consist of project intricacy, material schedule, and the shop's work, requiring mindful preparation to satisfy deadlines properly.

Are There Environmental Regulations Affecting Foundry Operations?

Yes, ecological guidelines greatly affect foundry procedures. These policies resolve discharges, waste monitoring, and source usage, ensuring that foundries follow sustainability that site methods while decreasing their ecological impact and promoting accountable production procedures.What Industries Frequently Utilize Professional Shop Solutions?

Lots of sectors utilize professional foundry solutions, including automobile, building, aerospace, and energy. These markets count on factories for producing important components, guaranteeing high quality materials, and conference certain manufacturing criteria important for their operational success.Specialist foundry services offer considerable benefits for manufacturers seeking top notch castings. While lots of suppliers seek to enhance their functional performance, specialist shop services offer a calculated benefit by noticeably conserving and decreasing prices time throughout the manufacturing process. Professional factory services enhance the production timeline (Precision aluminum casting). Inevitably, engaging with expert foundry solutions translates to an extra efficient manufacturing procedure, where more financial savings in both time and prices can extremely increase a business's affordable edge in the sector. Accessing sophisticated modern technology and competence with expert factory solutions considerably boosts a manufacturer's capabilities

Report this wiki page